Category

Popular

-

Magnetic Sine Plate Machinist

$ 650 – $ 780

Magnetic Sine Plate Machinist

$ 650 – $ 780

-

Premium Precision Grinding Vise/CNC Vise

$ 111 – $ 402

Premium Precision Grinding Vise/CNC Vise

$ 111 – $ 402

-

Customized Ceramic Step Gauge

Customized Ceramic Step Gauge

-

Magnetic Base Stand Holder

$ 55 – $ 118

Magnetic Base Stand Holder

$ 55 – $ 118

-

Ceramic Ring Gauge (Imperial/Metric)

Ceramic Ring Gauge (Imperial/Metric)

Tag Clouds

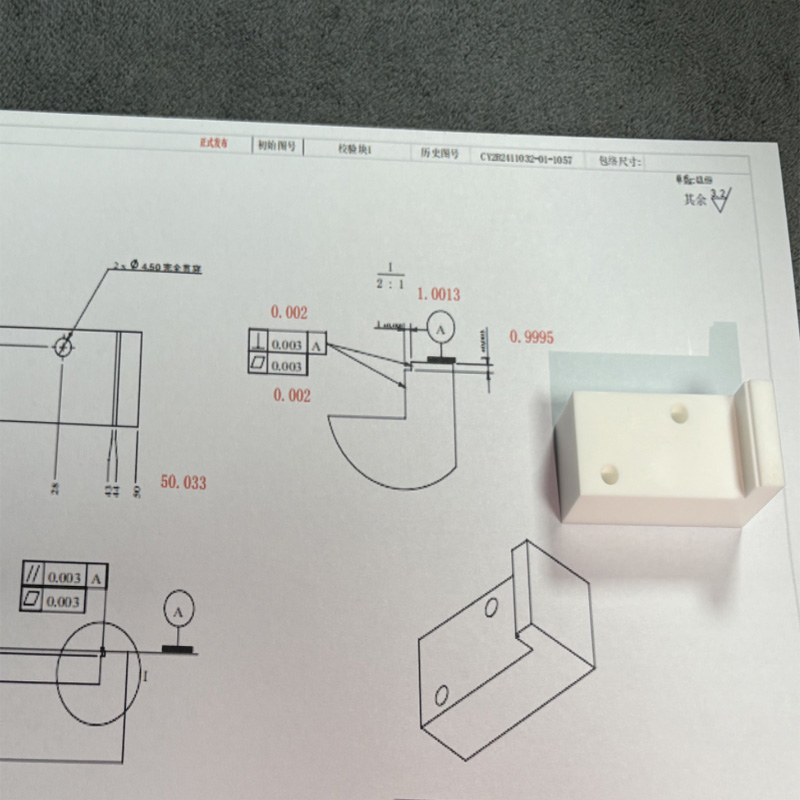

Customized High precision special-shaped fixture

We provide customized High precision special-shaped fixture, with accuracy of up to 0.002mm (2 μ m), 0.001mm (1 μ m), and 0.0005mm (0.5 μ m).

If there’s anything needed, please contact us.

The above display cases do not involve trade secrets. If you have confidentiality requirements, we can sign a confidentiality agreement. At that time, we will not display your product information to anyone

Custom Fixture Case Report

I. Project Background

Client Overview: The client for this project is a renowned electronics factory in China, specializing in the development and production of high-precision electronic products. With the escalating quality demands in the market, the factory has increasingly stringent requirements for fixture accuracy in its production processes to meet the manufacturing needs of its high-end electronic products.

II. Client Requirements

- Fixture Specifications: The client requested a customized fixture for precision assembly processes in its production line.

- Accuracy Requirements:

- Perpendicularity: ±0.003mm

- Flatness: ±0.003mm

- Parallelism: ±0.003mm

These extremely high accuracy requirements ensure that the fixture can stably and accurately position products during production, thereby enhancing production efficiency and product quality.

- Processing Time: The client expected a processing cycle of 5 days to meet its urgent production schedule.

- Material Selection: Considering environmental protection and durability, the client specified the use of industrial ceramics as the primary material for the fixture.

III. Project Execution

- Design and Planning:

- Based on the drawings and technical specifications provided by the client, our engineers conducted detailed design calculations to ensure that the fixture’s structure could meet all accuracy requirements.

- The design scheme underwent multiple internal reviews and client confirmations before being finalized.

- Material Procurement:

- High-quality, environmentally friendly industrial ceramics were selected as the raw material. This material boasts excellent wear resistance, corrosion resistance, and high hardness, making it ideal for the manufacture of high-precision fixtures.

- Processing and Manufacturing:

- Advanced CNC machining centers, combined with precision measurement equipment, were used for fine processing of the ceramic material.

- During the processing, each cutting parameter was strictly controlled to ensure that all dimensions and accuracy indicators of the fixture met the design requirements.

- After five days of intense processing, the fixture was successfully completed.

- Quality Inspection:

- A coordinate measuring machine (CMM) was used to conduct a full-dimensional inspection of the fixture to ensure that perpendicularity, flatness, and parallelism all met the accuracy requirement of ±0.003mm.

- Functional testing of the fixture was performed to verify its stability and reliability in simulated production environments.

IV. Project Outcomes

- Client Satisfaction: After rigorous quality inspection, the fixture met all the high-precision requirements specified by the client.

- Application of Eco-friendly Materials: The use of environmentally friendly industrial ceramics not only met the client’s specific requirements but also demonstrated our commitment to environmental protection.

- Efficient Delivery: Within the client’s specified 5-day processing cycle, we successfully completed the fixture’s manufacture and inspection, ensuring that the client’s production schedule remained unaffected.

V. Client Feedback

The client highly praised our work, stating that the fixture’s quality fully met its production needs, especially in terms of accuracy control. Additionally, the client specifically appreciated our rapid response and efficient execution capabilities, as well as the decision to use eco-friendly materials. This not only contributed to improving product quality but also aligned with its corporate philosophy of sustainable development.

VI. Conclusion

The successful implementation of this custom fixture project not only demonstrated our expertise in high-precision fixture manufacturing but also reflected our heightened focus on client needs and rapid response. In the future, we will continue to adhere to the principle of “Quality First, Client Supreme” and provide more clients with high-quality customized solutions.

Related products

-

Customized Gauge

Read moreWe provide customized gauge blocks and calibration blocks of various shapes and non-standard types, with accuracy of up to 0.002mm (2 μ m), 0.001mm (1 μ m), and 0.0005mm (0.5 μ m).

If there’s anything needed, please contact us.The above display cases do not involve trade secrets. If you have confidentiality requirements, we can sign a confidentiality agreement. At that time, we will not display your product information to anyone

-

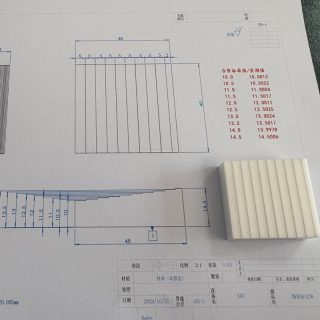

Customized case of ceramic gauge block

Read moreWe provide customized gauge blocks and calibration blocks of various shapes and non-standard types, with accuracy of up to 0.002mm (2 μ m), 0.001mm (1 μ m), and 0.0005mm (0.5 μ m).

If there’s anything needed, please contact us.The above display cases do not involve trade secrets. If you have confidentiality requirements, we can sign a confidentiality agreement. At that time, we will not display your product information to anyone

-

Customized Ceramic Step Gauge Block

Read moreWe provide customized gauge blocks and calibration blocks of various shapes and non-standard types, with accuracy of up to 0.002mm (2 μ m), 0.001mm (1 μ m), and 0.0005mm (0.5 μ m).

If there’s anything needed, please contact us.The above display cases do not involve trade secrets. If you have confidentiality requirements, we can sign a confidentiality agreement. At that time, we will not display your product information to anyone

-

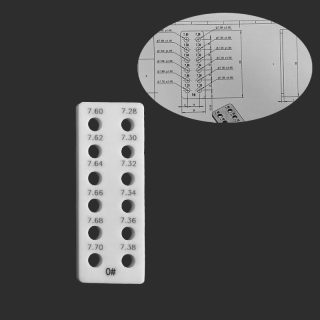

Customized Gauge Blocks/Customized ceramic fixtures

Read moreWe provide customized gauge blocks and calibration blocks of various shapes and non-standard types, with accuracy of up to 0.002mm (2 μ m), 0.001mm (1 μ m), and 0.0005mm (0.5 μ m).

If there’s anything needed, please contact us.The above display cases do not involve trade secrets. If you have confidentiality requirements, we can sign a confidentiality agreement. At that time, we will not display your product information to anyone

Best offers

Original Guaranteed

100% Safe

Secure Shopping

24x7 Support

Online 24 hours

Best Offers

Grab Now

Free Shiping

On all order over

Know Us

Our company founded in 2012, we specialize in the development and production of precision tools and measuring instruments under the brand name Liport-PMA. We provide customized solutions for electronics, machinery, medical, aerospace, and other industries, backed by extensive product experience and a skilled technical team. We look forward to collaborating with you for a brighter future.

Read More