Category

Popular

-

Magnetic Sine Plate Machinist

$ 650 – $ 780

Magnetic Sine Plate Machinist

$ 650 – $ 780

-

Premium Precision Grinding Vise/CNC Vise

$ 111 – $ 402

Premium Precision Grinding Vise/CNC Vise

$ 111 – $ 402

-

Customized Ceramic Step Gauge

Customized Ceramic Step Gauge

-

Magnetic Base Stand Holder

$ 55 – $ 118

Magnetic Base Stand Holder

$ 55 – $ 118

-

Ceramic Ring Gauge (Imperial/Metric)

Ceramic Ring Gauge (Imperial/Metric)

Tag Clouds

Customized Ceramic Step Gauge Block

We provide customized gauge blocks and calibration blocks of various shapes and non-standard types, with accuracy of up to 0.002mm (2 μ m), 0.001mm (1 μ m), and 0.0005mm (0.5 μ m).

If there’s anything needed, please contact us.

The above display cases do not involve trade secrets. If you have confidentiality requirements, we can sign a confidentiality agreement. At that time, we will not display your product information to anyone

Customized Ceramic Step Gauge Block Case

Background and Requirements

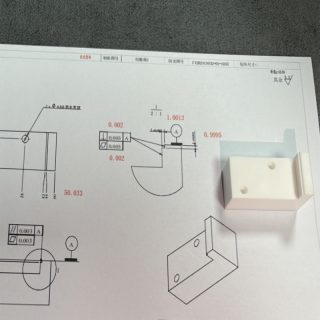

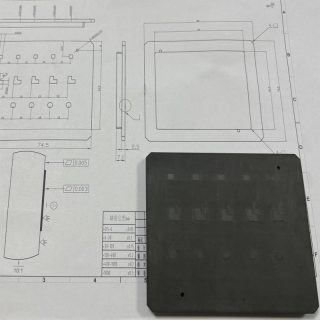

Recently, our factory received a customized order for ceramic step gauge blocks from a client. The client, a precision manufacturing enterprise, has extremely high requirements for the flatness and dimensional accuracy of the gauge blocks. They hoped that we could produce a batch of ceramic step gauge blocks for them, with all steps’ flatness and dimensions based on Surface A, and the tolerance controlled within ±0.005mm.

Production Process and Technical Requirements

To meet the client’s stringent requirements, our factory promptly organized a technical team to design and optimize the production plan. Ceramic materials possess excellent properties such as high hardness, wear resistance, and corrosion resistance. Therefore, during the production process, we adopted advanced ceramic processing technology and high-precision measurement equipment to ensure that the flatness and dimensional accuracy of the gauge blocks met the client’s requirements.

During the processing, we strictly followed the drawings and technical requirements provided by the client. Firstly, we utilized high-precision CNC machines to precision-process the ceramic materials, ensuring that the flatness and dimensions of each step met the design requirements. Secondly, we employed professional measurement tools to measure and calibrate the processed gauge blocks multiple times to ensure their accuracy met the client’s tolerance requirements.

Quality Inspection and Results

After the products were completed, we conducted rigorous quality inspections. To verify the flatness and dimensional accuracy of the gauge blocks, we selected ten key points for measurement. After measurement, we found that the errors at these ten points were all within ±0.003mm, far below the client’s required tolerance range of ±0.005mm. This result fully demonstrates that our production technology and product quality have reached the industry-leading level.

Client Feedback and Future Cooperation

When we shared this good news with the client, they highly recognized and praised our product quality and technical strength. The client expressed their intention to maintain a long-term partnership with us and hoped that we could continue to provide high-quality products and services in future collaborations.

Summary and Outlook

This successful case of customized ceramic step gauge blocks not only showcases our factory’s technical strength in ceramic processing and precision manufacturing but also earns us the trust and praise of the client. In the future, we will continue to adhere to the principle of “Quality First, Client Supreme” and continuously improve our technical expertise and production capacity to provide clients with even better products and services. At the same time, we also look forward to establishing cooperative relationships with more clients to jointly promote the development and progress of the precision manufacturing industry.

Related products

-

Customized High precision special-shaped fixture

Read moreWe provide customized High precision special-shaped fixture, with accuracy of up to 0.002mm (2 μ m), 0.001mm (1 μ m), and 0.0005mm (0.5 μ m).

If there’s anything needed, please contact us.The above display cases do not involve trade secrets. If you have confidentiality requirements, we can sign a confidentiality agreement. At that time, we will not display your product information to anyone

-

Ceramic Calibration Block Customization Case

Read moreWe provide customized gauge blocks and calibration blocks of various shapes and non-standard types, with accuracy of up to 0.002mm (2 μ m), 0.001mm (1 μ m), and 0.0005mm (0.5 μ m).

If there’s anything needed, please contact us.The above display cases do not involve trade secrets. If you have confidentiality requirements, we can sign a confidentiality agreement. At that time, we will not display your product information to anyone.

-

Customized case of ceramic gauge block

Read moreWe provide customized gauge blocks and calibration blocks of various shapes and non-standard types, with accuracy of up to 0.002mm (2 μ m), 0.001mm (1 μ m), and 0.0005mm (0.5 μ m).

If there’s anything needed, please contact us.The above display cases do not involve trade secrets. If you have confidentiality requirements, we can sign a confidentiality agreement. At that time, we will not display your product information to anyone

-

Customized Ceramic Step Gauge

Read more1. We can customize step gauges of different sizes and accuracies according to the drawings you provide or your needs.

2、We can provide metric and imperial step gauges.

3. Customization level: 0/1/2 levelThe above display cases do not involve trade secrets. If you have confidentiality requirements, we can sign a confidentiality agreement. At that time, we will not display your product information to anyone.

If needed, please contact our customer service

Best offers

Original Guaranteed

100% Safe

Secure Shopping

24x7 Support

Online 24 hours

Best Offers

Grab Now

Free Shiping

On all order over

Know Us

Our company founded in 2012, we specialize in the development and production of precision tools and measuring instruments under the brand name Liport-PMA. We provide customized solutions for electronics, machinery, medical, aerospace, and other industries, backed by extensive product experience and a skilled technical team. We look forward to collaborating with you for a brighter future.

Read More