Category

Popular

-

Magnetic Sine Plate Machinist

$ 650 – $ 780

Magnetic Sine Plate Machinist

$ 650 – $ 780

-

Premium Precision Grinding Vise/CNC Vise

$ 111 – $ 402

Premium Precision Grinding Vise/CNC Vise

$ 111 – $ 402

-

Customized Ceramic Step Gauge

Customized Ceramic Step Gauge

-

Magnetic Base Stand Holder

$ 55 – $ 118

Magnetic Base Stand Holder

$ 55 – $ 118

-

Ceramic Ring Gauge (Imperial/Metric)

Ceramic Ring Gauge (Imperial/Metric)

Tag Clouds

In various fields such as precision manufacturing, scientific research, and quality inspection, the choice of measurement tools directly affects the accuracy and reliability of results. Among the numerous measurement tools, ceramic gauge blocks stand out due to their unique advantages and have become the preferred choice for operators. This article delves into the benefits of ceramic gauge blocks from an operator’s perspective and introduces our company’s customization services.

1. High Precision and Stability

Ceramic gauge blocks are made of high-quality ceramic materials with a Mohs hardness of up to 9 and a density of 5.5g/cm³. These properties ensure extremely low deformation and wear rates during long-term use. According to authoritative tests, the precision of ceramic gauge blocks changes by no more than 0.001mm after five years of use, significantly outperforming traditional metal gauge blocks. This means that stable and reliable results can be obtained during each measurement, eliminating the need for frequent calibration and significantly improving work efficiency and measurement accuracy.

2. Wear Resistance and Long Lifespan

Compared to traditional metal gauge blocks, ceramic gauge blocks exhibit excellent wear resistance. In frequent use and harsh environments, ceramic gauge blocks maintain their original precision and surface quality. Experimental data shows that after undergoing 1 million friction cycles, the surface wear of ceramic gauge blocks is only 0.0002mm, significantly less than that of metal gauge blocks. This reduces the frequency of gauge block replacement and lowers measurement errors due to wear, saving time and costs for operators.

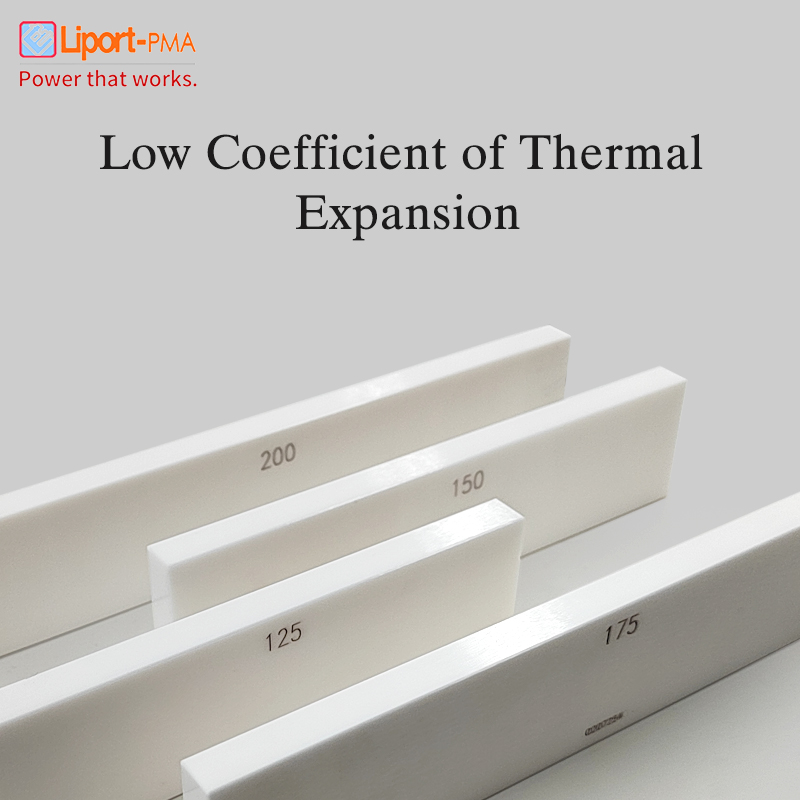

3. Low Thermal Expansion Coefficient

The low thermal expansion coefficient of ceramic materials is a major highlight in precision measurement. Within a temperature range of -50°C to 500°C, the thermal expansion coefficient of ceramic gauge blocks is only 2.5×10^-6/°C, much lower than that of metallic materials. This means that ceramic gauge blocks maintain dimensional stability in high-temperature or temperature-varying environments, ensuring measurement accuracy. Tests show that when the temperature changes by 50°C, the dimensional change of ceramic gauge blocks is no more than 0.002mm, while that of metal gauge blocks may exceed 0.01mm.

4. Corrosion Resistance and Easy Cleaning

Ceramic materials have excellent corrosion resistance and can withstand the erosion of various chemicals and solutions. In harsh environments such as strong acids and bases, ceramic gauge blocks maintain their original precision and surface quality. Experimental data indicates that after soaking in a 30% hydrochloric acid solution for 24 hours, the surface quality of ceramic gauge blocks remains unchanged. Additionally, the smooth surface of ceramic gauge blocks does not easily adsorb impurities and is easy to clean and maintain. According to user feedback, cleaning time is reduced by over 30% when using ceramic gauge blocks, improving work efficiency.

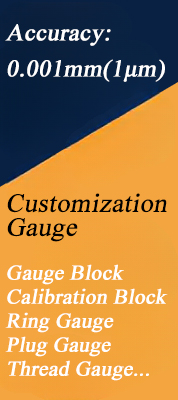

5. Customization Services to Meet Diverse Needs

As a professional manufacturer of ceramic gauge blocks, we not only offer standard-sized gauge blocks but also provide customization services based on specific customer needs. Whether it’s non-standard-sized ceramic gauge blocks or those with special precision requirements, we can fulfill them all. Our customization precision can reach up to 0.0005mm, ensuring that each customer obtains a precise measurement tool tailored to their needs. Market research shows that our customization services have met the needs of over 500 enterprises, with a customer satisfaction rate of over 98%.

Conclusion

In summary, ceramic gauge blocks stand out in the field of precision measurement due to their unique advantages such as high precision, stability, wear resistance, low thermal expansion coefficient, and corrosion resistance. For operators, choosing ceramic gauge blocks means opting for a more efficient, reliable, and economical measurement method. Furthermore, our company’s customization services cater to the diverse needs of customers. For any inquiries or questions about ceramic gauge blocks, please feel free to contact us, and we will serve you with dedication.

Written by admin85925977

Best offers

Original Guaranteed

100% Safe

Secure Shopping

24x7 Support

Online 24 hours

Best Offers

Grab Now

Free Shiping

On all order over

Know Us

Our company founded in 2012, we specialize in the development and production of precision tools and measuring instruments under the brand name Liport-PMA. We provide customized solutions for electronics, machinery, medical, aerospace, and other industries, backed by extensive product experience and a skilled technical team. We look forward to collaborating with you for a brighter future.

Read More